Beim Shure V15 Type IV lag ein kleines Heftchen dabei .....

...... und in diesem Heftchen stand in wirklich allerkleinster Schrift, was es mit diesem Edel-Abtaster so auf sich hat. Auch, welche Ersatznadeln sinvoll sind, wird hier recht genau und offen beschrieben. Wer dieses Heftchen hatte, der hatte ja das System bereits gekauft, also konnte man (beinahe) auf diese typischen Werbesprüche verzichten. Jedenfalls ist (und war) es nicht normal, daß der (bzw. ein) Hersteller wirklich alle Spezifikationen so offen publizierte.

.

ERA IV - Shure V15 Type IV - SUPER TRACK IV

Hier doch noch einige Werbesprüche : The Shute V15 / IV does more...

The creation of the V15 Type IV is something of a "tour de force" in innovative engineering. The challenge was to design a cartridge that would transcend all existing cartridges in musical transparency, technical excellence, and uniformity.

The unprecedented research and design disciplines that were brought to bear on this challenge over a period of several years have resulted in an altogether new pickup system that exceeds previous performance levels by a significant degree — not merely in one parameter, but in totality.

In fact, this pickup system has prevailed simultaneously over several extremely difficult music re-creation problems which, until now, have defied practical solutions. Most of all, this is an eminently musical cartridge which is a delight to the critical ear, regardless of program material, or the rigorous demands of today's most technically advanced recordings.

.

SUPER TRACK IV - An elegant solution to many prevalent problems

The V15 Type IV is a Stabilized, Static-free, Super-Trackability cartridge-stylus system. The next few pages wall explain the following advantages of the SUPER TRACK IV™ system:

- • Demonstrably improved trackability across the entire audible spectrum — especially in the critical mid- and high-frequency areas.

- • Dynamically stabilized tracking overcomes record-warp caused problems, such as fluctuating tracking force, varying tracking angle and wow.

- • Electrostatic neutralization of the record surface minimizes three separate problems: static discharge; electrostatic attraction of the cartridge to the record; and attraction of dust tothe record.

- • An effective dust and lint removal system.

- • A Hyperelliptical stylus tip configuration dramatically reduces both harmonic and intermodulation distortion.

- • Ultra-flat response — individually tested to meet all specifications.

- • Reduced dynamic mechanical impedance allows superb performance at ultra-light tracking forces.

.

Contents:

| Trackabilitv................................... | 4-5 |

| Warp .................................................. | 6 |

| Static ................................................ | 7 |

| Dust .................................................... | 8 |

| Stylus Information .......... | 9, 13; 15 |

| Installation ............................. | 10-12 |

| Operation..................................... | 13 |

| Care and Cleaning ................ | 13-14 |

| Specifications and Dimensions ......................... | 14-15 |

| Warranty........................................ | 16 |

.

READ ON...

.

The new frontiers of trackability

Trackability - the ability of the stylus to stay in contact with both groove walls - remains the one overwhelming measure of a cartridge's overall performance.

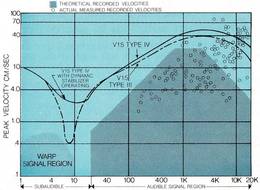

The chart at right shows a hitherto unattainable excellence in trackability, at super-light, record- and stylus tip-saving forces.

- Anmerkung : Das ist leider ganz großer Quatsch, denn der Verschleiß an der Nadelspitze selbst eines Diamanten ist von der Auflagekraft nahezu unabhängig, wie in dieser Dissertation von Dr. Schwartz von der UNI Karlsruhe hergeleitet wird.

.

However, consistent tracking has always been challenged by such additional ever-present factors as warp, static, lint and dust - especially when these factors combine with wide dynamic range "hot" recordings. The many new design features of the V15 Type IV permit the stylus to achieve and maintain unprecedented trackability with a consistency never before possible.

In the following chart, the shaded area at bottom left represents the envelope of actual warp signals found on records. The shaded area at right represents recommended theoretical limits of record cutting velocities. The scattered points are the "hottest" recorded velocities actually measured on difficult-to-track records. Although a cartridge with moderate trackability will be able to track all the recorded velocities encompassed within the theoretical cutting stylus limits, substantially higher trackability is needed to track recorded velocities actually found on today's discs.

The V15 Type IV tracks more of the "hottest" points at a low stylus force than any other existing cartridge. The curve shown is for 1 gram tracking force. By increasing the tracking force to 1-1/4 grams, even more of these points - virtually all records produced thus far - will be tracked.

Also, note the revolutionary subaudible warp signal range trackability characteristics of the Super Track IV™, discussed in detail on Page Six.

.

* Cartridge-tone arm system trackability as mounted in SME 3009 tone arm at 1 gram tracking force.

.

Coping with "hot" recorded signals...

The "hot" signal problem

The stylus cannot track the heavily modulated signals found on many of the newest records.

Its Symptoms

The stylus mistracks and produces distortion and buzzing sounds. While mistracking can occur at any frequency, extreme mistracking occurs most at high frequencies. Extreme mistracking can irreparably damage the record groove.

.

The Super Track IV™ total design solution

The V15 Type IV has a new stylus assembly designed for dramatically increased trackability as the result of two significant improvements.

A. The effective stylus mass of the conventional moving system bas been lowered by utilizing a telescoped shank structure (No. 1 in figure at left) and a new lightweight high-energy magnet (No. 2). The reduced effective mass of the new structure helps improve trackability in the critical mid-and high-frequencies.

B. Incorporating a newly designed two-function bearing system (No. 3) has bypassed previously necessary design compromises. The new bearing system is independently optimized for low frequencies and for high frequencies so that trackability is enhanced across the entire audio spectrum.

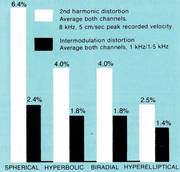

The V15 Type IV has a Hyperelliptical nude diamond tip <No .4) that results in an elongated tip-groove contact area. The new tip provides as much as a 25% reduction in distortion over a conventional biradial (elliptical) stylus*.

*See graph on Page Nine.

.

Our war on warp ...

The warp problem

Sub audible record waips and low-frequency arm-cartridge resonance interfere with the ability of the stylus to track audio signals.

.

Its Symptoms

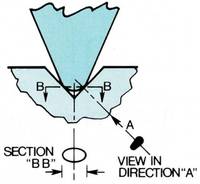

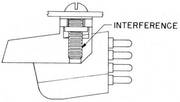

Reactions of the playback system to very low frequency warps (between 0.5 and 8 Hz as shown in the trackability chart on Page 4) on the record surface can result in gross changes in the distance between the cartridge and the record.

The distance change alters the stylus tracking force and the vertical tracking angle, illustrated in the sketches above. This can cause groove skipping, cartridge bottoming, signal wow, and, occasionally, amplifier and/or speaker overload.

Worst of all, trackability at all frequencies is diminished by these warp-caused changes in tracking force. At some very low frequency (typically from 5 to 15 Hz), the tone arm-cartridge combination has a resonance frequency. When the arm-cartridge resonance frequency coincides with the waip frequency, all the enumerated symptoms are exaggerated. In addition, there is a sudden, very large increase in output at resonance.

.

The Super Track IV™ total design solution

A viscous-damped "Dynamic Stabilizer" combines with the new stylus assembly described on Page 5 to raise the arm-cartridge resonance frequency and attenuate the arm-cartridge system resonance effect. The following graph shows the output at resonance with and without the Stabilizer.

Die Grafik rechts : V15 Type IV Cartridge; Mounted In SME 3009 Improved Tone Arm, STR 120 Test Record, Vertical Modulation, 16 2/3 RPM.

.

The Dynamic Stabilizer is viscous-damped to resist sudden changes in motion, such as those caused by subaudible warp. Instead, the damping ensures that the tone arm will follow the irregularities of the record surface, even at the frequency of arm-cartridge resonance. The original cartridge-to-record distance is thus maintained, and vertical tracking angle and stylus tracking force remain constant! Stabilizing the distance, angle, and force ensures that the full tracking capability of the cartridge is realized at all times.

.

The double-faceted problem of electrostatic charges...

.

The static problem

.

- A. Static electricity on the record surface attracts the cartridge to the record.

- B. Static electricity on the record surface is discharged through the stylus.

.

Its Symptoms

.

A. Static charges on the record are omnipresent and unevenly distributed. Therefore, they attract the cartridge unevenly and change the arm-to-record distance, the vertical tracking angle, and stylus tracking force. The result is undesirable wow and flutter.

B. The static discharge through the stylus and amplifying system can cause annoying pops and clicks.

.

The Super Track IV™ total design solution

The fibers in the Dynamic Stabilizer that look like an off-center dust brush are actually electrically conductive. The fibers ride on the surface of the record, pick up the static electricity and discharge it to ground, much like a miniature lightning rod *. As a result, the record surface is electrically neutralized.

Static charges on the record can be caused by contact with the record jacket, the turntable mat, or other records. During play, the record-contact fibers continuously sweep the inner groove charge just ahead of the stylus, preparing the groove about to be played.

The static charge is thus prevented frpm affecting the arm-to-record distance, or from causing static noise in the amplifier and loudspeakers. (Clicks and pops due to other causes may mask some of the reduction of static noise.) The removal of static charges stabilizes tracking force during the entire record playing process.

*In fact, the static discharge feature will be reasonably effective even when the Dynamic Stabilizer is in the "Up" position and the fibers are not in contact with the record surface.

.

Cleaning up Dust .....

.

The dust problem

Dust particles on the surface of the record, or in the record groove, result in an accumulated "dust ball" on the stylus tip which interferes with pickup of "clean" signals.

.

Its Symptoms

Faulty tracking; distorted signals, groove jumping, and ultimate record damage can be caused when the stylus collects the dust instead of tracking the record signals. Particles that accumulate and foul the tip prevent accurate tracking and can cause loss of contact with the record surface, with resulting gross distortion.

.

The Super TracklV™ total design solution

The record-contact fibers in the Dynamic Stabilizer are composed of more than 10,000 ultra-fine strands. Each strand has a diameter of approximately 7.6 microns (.0003 in.). These strands fit down into the groove, removing interfering dust and sweeping the record clean. And, dust is not ground into the groove walls.

.

Impact Protection .....

.

The impact problem

When the arm is accidentally dropped on the record, the delicate stylus assembly is subjected to the full shock at contact. Because the stylus is springy, it can bounce across the record and create several points of groove damage.

.

Its Symptoms

The stylus may be permanently damaged, even inoperative. The record is permanently impressed with several audible "pop" points.

.

The Super Track IV™ total design solution

In its normal operating position, the Dynamic Stabilizer is a shock absorber which cushions the impact from an accidental arm drop. The Dynamic Stabilizer takes the force of the blow, and eliminates further bouncing of the stylus.

.

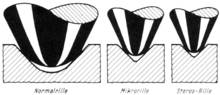

The Hyperelliptical Stylus tip

The Hyperelliptical nude diamond tip configuration of the V15 Type IV represents a significant advance in tip design for stereo sound reproduction. As the above figures show, its "footprint" (represented by black oval) is longer and narrower than the traditional Biradial (Elliptical) tip-groove contact area.

Because the Hyperelliptical footprint geometry is narrower than both the Biradial and long-contact shapes such as the Hyperbolic, it is preeminent for reproduction of the stereo-cut groove. In fact, as a result of the optimized contact area of the Hyperelliptical tip, both harmonic distortion (white bars in graph at right) and intermodulation distortion (black bars) are dramatically reduced.

.

Step 1: stylus removal and replacement

.

Important: Always remove the stylus before making connections or mounting the cartridge. The cartridge's Dynamic Stabilizer should be in the "guard" position throughout (see illustrations at top of page). Exercise care so your fingers don't slip and damage the stylus tip or shank.

.

Step 2: electrical connections

This cartridge has four terminals with a separate ground terminal for each channel. For stereo, terminal "L" and its ground terminal "LG" represent the left channel (inside groove wall). Terminal "R" and its ground terminal "RG" represent the right channel (outside groove wall).

Connect the cartridge as shown in the illustration below. Note that, in many tone arms, lead wiring is color coded and matches this cartridge's color coded terminals.

.

Step 3: mounting the cartridge

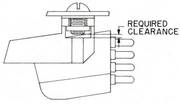

The cartridge has 12.7 mm (1/2 in.) mounting centers. Mounting hardware is provided. (Refer to the tone arm manual for further specific details, such as the need for spacers.)

.

DO NOT REPLACE THE SYTLUS UNTIL ELECTRICAL CONNECTIONS ARE MADE AND THE MOUNTING IS COMPLETED.

The two basic mounting methods are:

- 1. Mounting the cartridge in a tone arm shell that has unthreaded clearance holes.

- 2. Mounting the cartridge in a tone arm shell that has threaded mounting holes.

Use the thin plastic retainer provided in the hardware pack in both methods. The retainer holds the screws in place either on the shell (method 1) or on the cartridge (method 2). IMPORTANT: When using method 1 (mounting in a shell that has unthreaded clearance holes) select the shortest screws that will hold the cartridge securely. The screws should not extend through the mounting plate and beyond the window in the mounting block (see illustration below).

.

Step 4: setting the tracking and antiskating force

Replace the stylus in the cartridge (see Step 1).

Follow the tone arm manufacturer's instructions for cartridge and stylus tip position, and for balancing the tone arm. For optimum playing position, the bottom edge of the silver mounting block should be parallel to the record.

.

TRACKING FORCE

with the dynamic stabilizer operating ... This cartridge is designed for a stylus tip tracking force range of 0.75 to 1.25 grams. When the viscous-damped Dynamic Stabilizer is in the operating position (see illustration above), it exerts a force on the record of 0.5 grams that

must also be accommodated in the total tone arm tracking force setting.

Therefore, use the following settings:

| To obtain this force at the stylus tip | Set the arm tracking force adjustment to |

| 0.75 grams | 1.25 grams |

| 1.0 gram 1.25 grams | 1.5 grams 1.75 grams |

.

When using an external gauge such as the Shure SFG-2 Stylus Force Gauge for setting tracking force, lock the Dynamic Stabilizer in the "up" position and set the tracking force as shown for the arm above.

(When the Dynamic Stabilizer rides on the record with the cartridge in use, the extra 0.5 grams will be offset by the Dynamic Stabilizer and WILL NOT APPEAR AT THE STYLUS TIP. The tip force will be that shown in the first column.) with the dynamic stabilizer up ...

If, for any reason, the cartridge is used with the Dynamic Stabilizer in the "up" position, the tracking force should be set as recommended for the tip, i.e., from 0.75 to 1.25 grams.

NOTE: Do not exceed the maximum tracking forces of 1.75 grams when the cartridge is used with the Dynamic Stabilizer in the "operating" position, or 1.25 grams when used with the Dynamic Stabilizer in the "up" position.

.

ANTISKATING FORCE

Set the antiskate mechanism according to the tone arm manufacturer's directions. Use an antiskating force corresponding to the total tone arm tracking force settine. (Column 2 in chart. above)

.

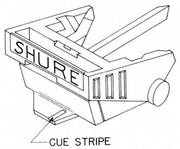

Step 5: operation

Before playing the first record, carefully place the Dynamic Stabilizer in the "operating" position so that it floats below the cartridge. The cartridge is now ready to use. For manual play, the white cue stripe on the Dynamic Stabilizer assists in accurate set-down by showing the stylus tip position.

This cartridge should be used only in arms especially designed for low tracking forces. Such arms should have low friction at all bearing surfaces (the Shure/SME tone arm is an example).

Although this cartridge will track records at a stylus tip force of 0.75 grams, it may be desirable in some tone arms to increase the tracking force for optimum results.

NOTE: See further instructions under Cleaning.

.

A NOTE ON COMPATIBILITY WITH VARIOUS RECORD FORMATS

The V15 IV is suitable for all four-channel matrix records and will play monophonic LPs as well as stereo records. It will play 78 rpm records when fitted with a VN478E stylus described on Page 15.

.

- Anmerkung : Das stimmt so auch nicht. Die älteren Mono Platten hatten einen anderen Schnitt für dickere Diamantspitzen als die späteren Stereo Platten. Siehe die Grafik rechts. Nur hatte das damals niemand kritisiert, weil teilweise das Wissen fehlte.

.

Step 6: cleaning

For best performance, clean both the stylus tip and the fibers of the Dynamic Stabilizer regularly.

- CLEANING THE STYLUS TIP

Use the supplied brush. Always brush the stylus from back to front; never brush or wipe the stylus from front to back, or side to side. An alcohol or alcohol-distilled water solution can be used as a cleaning agent. Commercial cleaning solutions may cause stylus damage or corrosion. - CLEANING THE DYNAMIC STABILIZER

Use the supplied brush. Use no fluids. Carefully clean the dust out of the fibers using a back to front movement. Brush the fibers long enough to remove the fine particles between the fibers as well as any mat of lint on the surface. Take care not to catch the stylus shank or tip when cleaning the Dynamic Stabilizer brush.

NOTE: After installation (or a prolonged period of not having been used), make certain that no foreign matter has lodged between the cartridge body and the Dynamic Stabilizer, immobilizing it.

A simple method is to move the Stabilizer carefully from "up" to "guard" several times. This will ensure proper performance. Also check the stylus tip to make certain that no foreign matter has accumulated. If it has, follow the recommended stylus tip cleaning method.

.

Shure V15 Type IV Dimensions

preserving stylus life

.

- 1. Follow turntable or tone arm instructions when adjusting antiskating force in the suspension system of the tone arm.

- 2. Do not handle the tone arm while it is in operation since this may cause the arm to sweep across the record.

- 3. If it is necessary to manually place the tone arm in the record groove while turntable is rotating, release it as the Dynamic Stabilizer sets down on the record or as the stylus engages the record groove.

- 4. Correct improper set-down adjustment or malfunction of the turntable changing mechanism to prevent the stylus from striking the edge of the turntable or record. Do not stack more records than turntable manufacturer recommends.

- 5. Take care to properly insert the stylus into the cartridge assembly and the cartridge and shell assembly into the tone arm receptacle.

- 6. Use proper vertical tracking force setting for each cartridge.

- 7. Do not use damaged records.

- 8. When dusting the turntable protect the stylus with the Dynamic Stabilizer locked in the guard position.

.

Shure V15 Type IV and V15 IV-G Specifications

.

Typical Trackability (in SME Tone Arm at 1 gram tip tracking force, in cm/sec peak recorded velocity):

| 400 Hz | 29 cm/sec |

| 1,000 Hz | 42 cm/sec |

| 5,000 Hz | 47 cm/sec |

| 10,000 Hz | 37 cm/sec |

.

- Output Voltage (at 1,000 Hz, 5 cm/sec peak recorded velocity): 4.0 mV per channel

- Channel Balance: Within 2 dB

- Channel Separation (minimum): 25 dB at 1,000 Hz, 15 dB at 10,000 Hz

- Optimum Load: 47,000 ohms resistance in parallel with 200 to 300 picofarads capacitance per channel. Load resistance can be up to 70,000 ohms with almost no audible change in frequency response. Total capacitance includes both the tone arm wiring and amplifier input circuit. (Most amplifiers, tone arms and cables meet this requirement.)

- Inductance: 500 millihenries

- DC Resistance: 1380 ohms.

.

| Tracking_Force: | Force at the stylus tip | Total tone arm setting with Dynamic Stabilizer "operating" |

| Minimum | 0.75 grams | 1.25 grams |

| 1.0 gram | 1.5 grams | |

| Maximum | 1.25 grams | 1.75 grams |

.

- Force Exerted by Dynamic Stabilizer: 0.5 grams

- Output Terminals: 4 terminals

- Mounting: 12.7 mm (standard 1/2 in.) mounting centers

- Net Weight: 6.4 grams

.

V15 Type IV Styli Available :

| VN45HE | Hyperelliptical Nude Diamond Tip, Black Grip, Black Nameplate. |

| VN4G | Spherical Nude Diamond Tip, 15 microns (.0006 in.) radius, |

| Black Grip, Gray Nameplate (supplied in V15 IV-G Cartridge). | |

| VN478E | Biradial (Elliptical) Nude Diamond Tip. For monophonic 78 rpm records. Tip Tracking Force Range: 0.75 to 1.25 grams. 13 x 63 microns (.0005 in. x .0025 in.). |

Full One Year Warranty

Shure Brothers Incorporated ("Shure"), 222 Hartrey Avenue, Evanston, Illinois 60204, warrants to the owner of this product that it will be free, in normal use, of any defects in workmanship and materials for a period of one year from date of purchase. You should retain proof of date of purchase. Shure is not liable for any consequential damages. If this Shure product has any defects as described above, carefully repack the unit and return it prepaid to:

Shure Brothers Incorporated - Attention: Service Department - 1501 West Shure Drive Arlington Heights, Illinois 60004

If you are not in the United States, return the unit to your dealer or Authorized Service Center for repair. The unit will be repaired or replaced and returned to you promptly, and if it cannot be repaired or replaced, you may elect to receive a refund. This warranty does not include stylus wear.

.

PATENT NOTICE:

Cartridge and stylus manufactured under one or more of the following U.S. Patents 3,055,988, 3,077,521, 3,077,522, and 3,463,889. Other patents pending.

Quality Assurance Certificate - Shure V15 Type IV Cartridges

The V15 Type IV Stereo Dynetic® Cartridge has been manufactured under the Shure Master Quality Control Program. This program embraces stringent safeguards and standards to assure you that your V15 Type IV is in perfect operating condition.

Shure quality control not only covers incomingparts and the finished products, but intermediate subassemblies as well. For example: every individual cartridge body and every stylus-magnet assembly is tested and microscopically examined. Each finished cartridge is individually subjected to exacting listening tests, and tested electrically and mechanically against close tolerance performance specifications seldom achieved in the High Fidelity Industry.

SPECIAL NOTE:

To maintain the original performance standards of your cartridge, be certain that any replacement stylus you buy bears the following certification on the package:

"This Stereo Dynetic® stylus is precision manufactured by Shure Brothers Inc."

AVOID INFERIOR IMITATIONS. THEY WILL SERIOUSLY DEGRADE THE PERFORMANCE OF YOUR CARTRIDGE. ALL GENUINE "DYNETIC®" STYLI ARE MANUFACTURED BY SHURE BROTHERS INC. LOOK FOR THE NAME SHURE ON THE STYLUS GRIP.

Copyright 1978 SHURE BROTHERS INC. 222 Hartrey Avenue, Evanston, Illinois 60204 27A1303 (RG)

Printed in U.S.A.

.